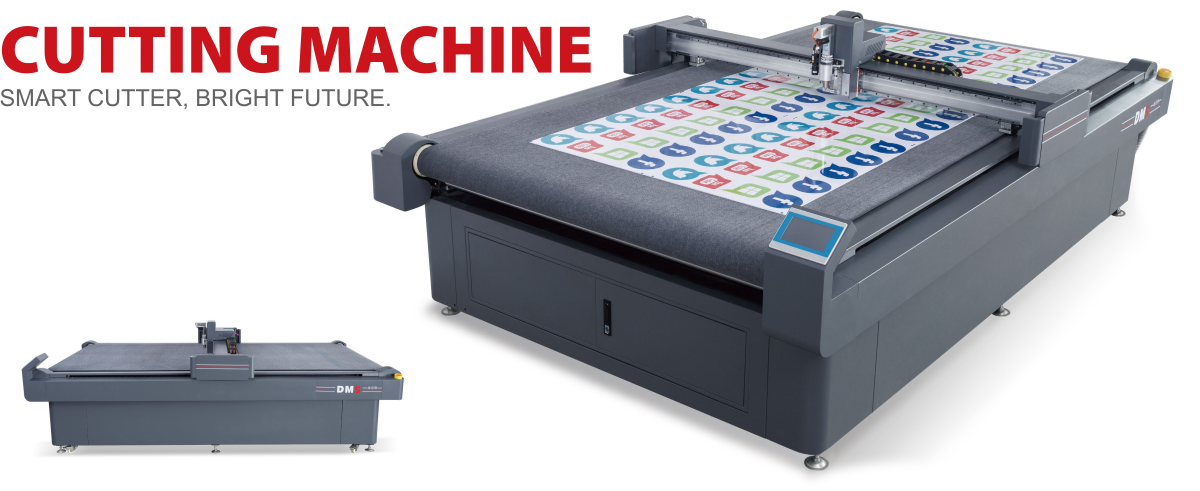

The luggage industry is complex in process, high in requirements for the division, and low in proofing efficiency. The computer proofing machine of DMS luggage industry can easily complete the high-demand process such as arc-throwing and wrinkle-removing. The proofing process is smooth and the cutting arc is perfect; the rolling platform is fully automatic. The automatic cutting of the feeding material has the advantages of saving time and materials; it can also cut various graphics, which is convenient and quick, and archives and calculates the design draft through the CAD self-contained software, which greatly improves the proofing efficiency and quality;

DMS luggage industry computer proofing machine:

1. Overcut optimization function: Using CAM software independently developed by TPS, system optimization of tool physical overcut phenomenon, maximum reduction of graphic contour, bringing perfect cutting effect to customers

2. Intelligent countertop compensation function: the flatness of the countertop is detected by a high-precision distance detector, and the plane is corrected in real time by software to ensure high-quality cutting effect.

3. Positive and negative cutting function: combined with the desktop detection function to realize intelligent positive and negative graphic cutting function

4. Automatic tool setting function: fast and simple automatic tool setting system, using fiber laser sensor to accurately detect the tool and improve the efficiency of tool setting

5. Tool quick change module: simple and efficient tool holder quick change system, making operation easier and convenient

6. Multi-task efficient cycle cutting, intelligent adsorption configuration

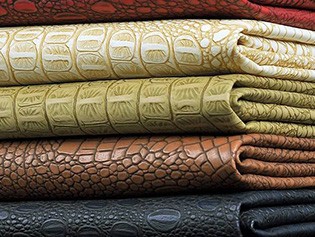

Adaptor & Application Materials

-

Leather cutting machine

Tool selection -

Leather cutting machine

Tool selection -

Leather cutting machine

Tool selection -

Leather cutting machine

Tool selection -

Solid color leather cutting machine

Tool selection

Head design

With a convenient and replaceable head design concept, the tool heads with different functions can be replaced and added according to actual needs.

Communication

The data interface is a Gigabit network interface, which enables remote upgrade and maintenance, and the transmission speed is fast and the distance is long.

Countertop

Adopting advanced and mature rolling table design, aluminum “honeycomb” vacuum adsorption platform maintains a flat cutting platform and improves cutting precision.

Control System

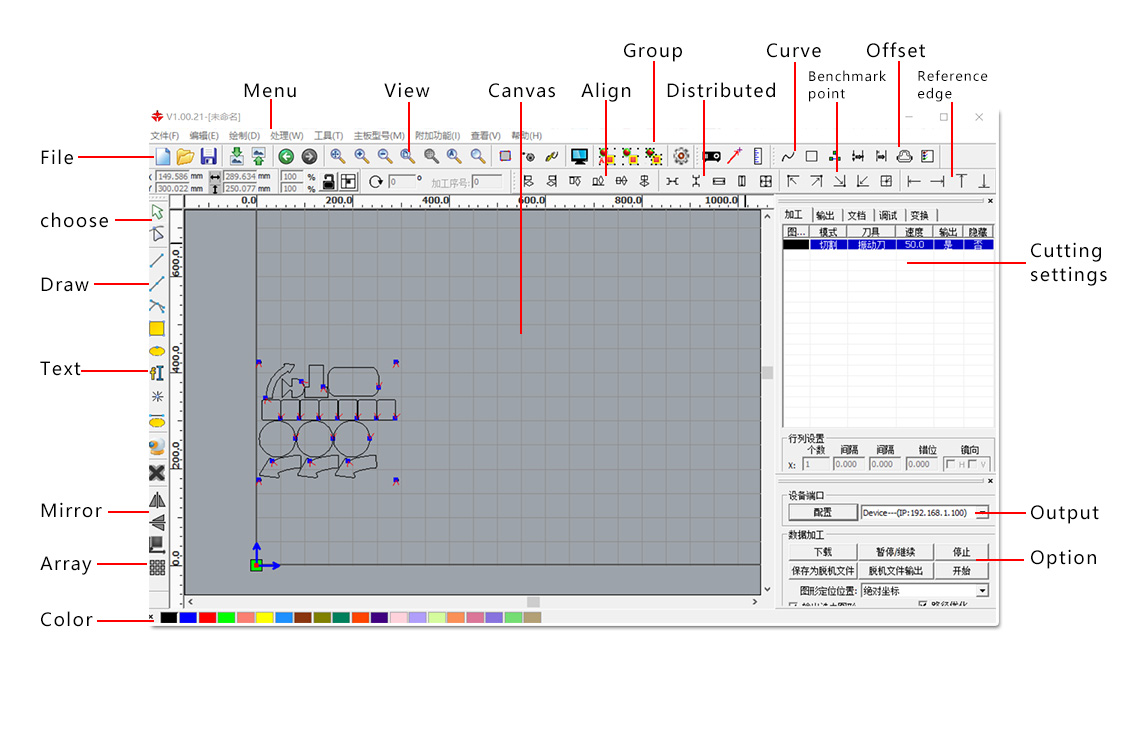

Independent research and development of human-machine interface operating system, humanized design, intelligent recognition of knife cutting, fast capture of cutting targets.

Imported felt

Imported felt, wear-resistant, breathable, ensuring high flatness of the cutting platform.

Collision avoidance

Safety anti-collision system to ensure the safety of operators.

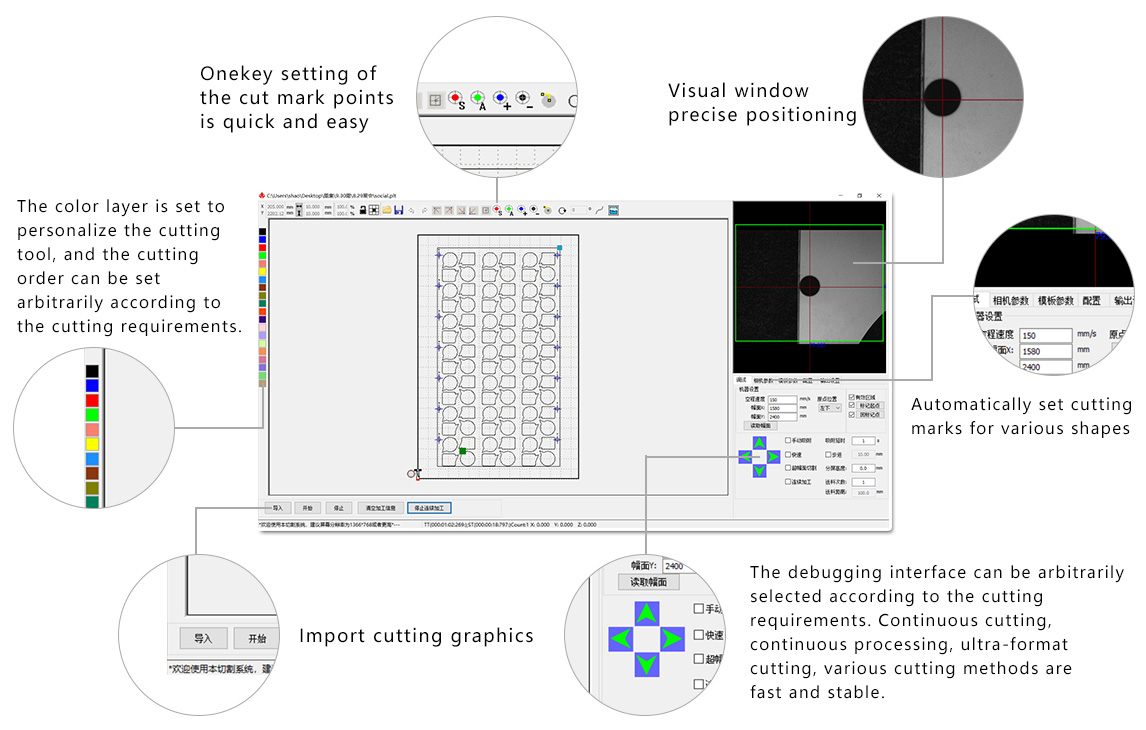

Digital cutting machine software features

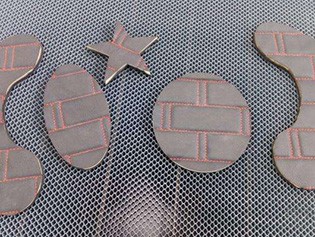

DMS digital cutting machine adopts self-developed CAM software, and user requirements are perfectly integrated into software design. It is a fully automatic intelligent cutting system that combines the three advantages of performance, speed and quality, which can complete full cutting, half cutting, boring and milling, and quickly. Various processes such as punching, crease, marking, etc., the operation is simple and convenient, the function is rich and practical, and the tool quick change module can meet the customization requirements of the user.

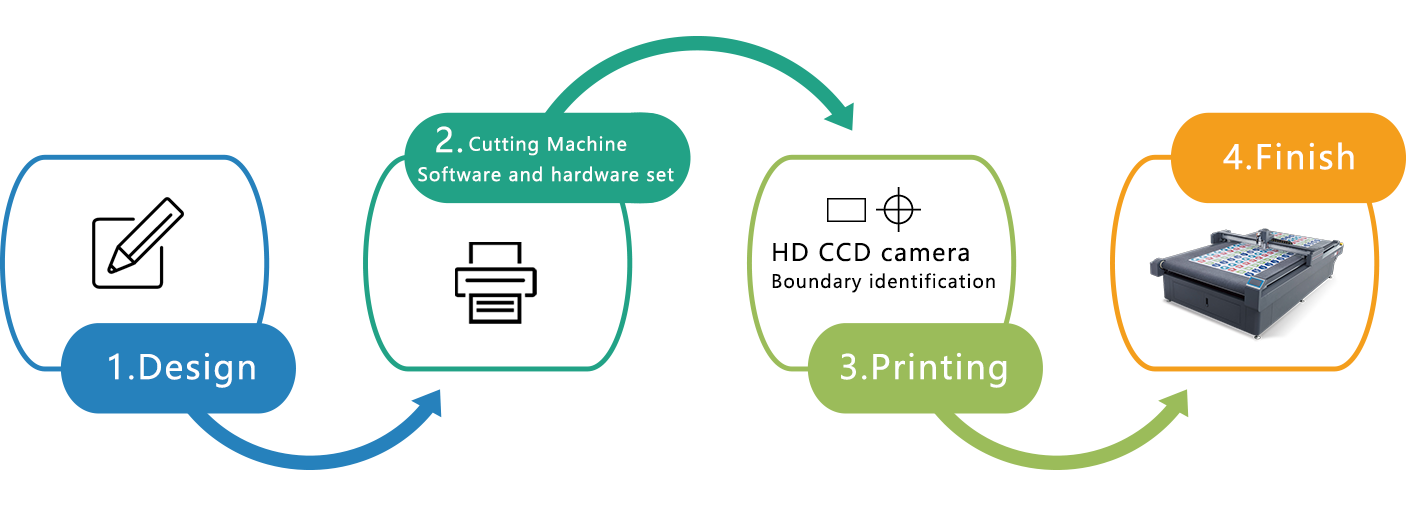

Schematic diagram of the cutting process

Leather bag cutting machine cutting Technical Parameters

Main technical parameters of the equipment

| Technical parameters / model | DMS-2516A |

| Multi-function | Tools can be easily changed, with ornamental engraving, milling, vibration cutting, half cutting and creasing, drawing, the cursor position and optional precise camera position |

| Safety device | Using infrared sensors, respondive, safe |

| Moving speed | 800-1500mm/s |

| Cutting speed | 200-1200mm/s(according to different cutting materials) |

| Cutting thickness | 40mm(More than 40mm can be customized |

| Material Fixed | Vaccum System |

| Cutting tolerance | ±0.05mm |

| Servo resolution | ±0.01mm |

| Transmission interface | Ethernet |

| Network transmission distance | ≤350 m |

| Buffer capacity | 2GB |

| Transmission system | Import (Digital servo motor、Linear guide、Synchronous belt、Screw、Gear) |

| Normal power | 7.5-11KW |

| Voltage | 380V± 10% |

| Working Range | 2500×1600mm |

| Max feeding width | 1600mm |

| Product size | 3521×2186×1280mm |

| Packing Size | 3670×2340×1500mm |

| Gross Weight | 1150KGS |

DMS Electrical and Mechanical Equipment Co.,Ltd. all rights reserved.